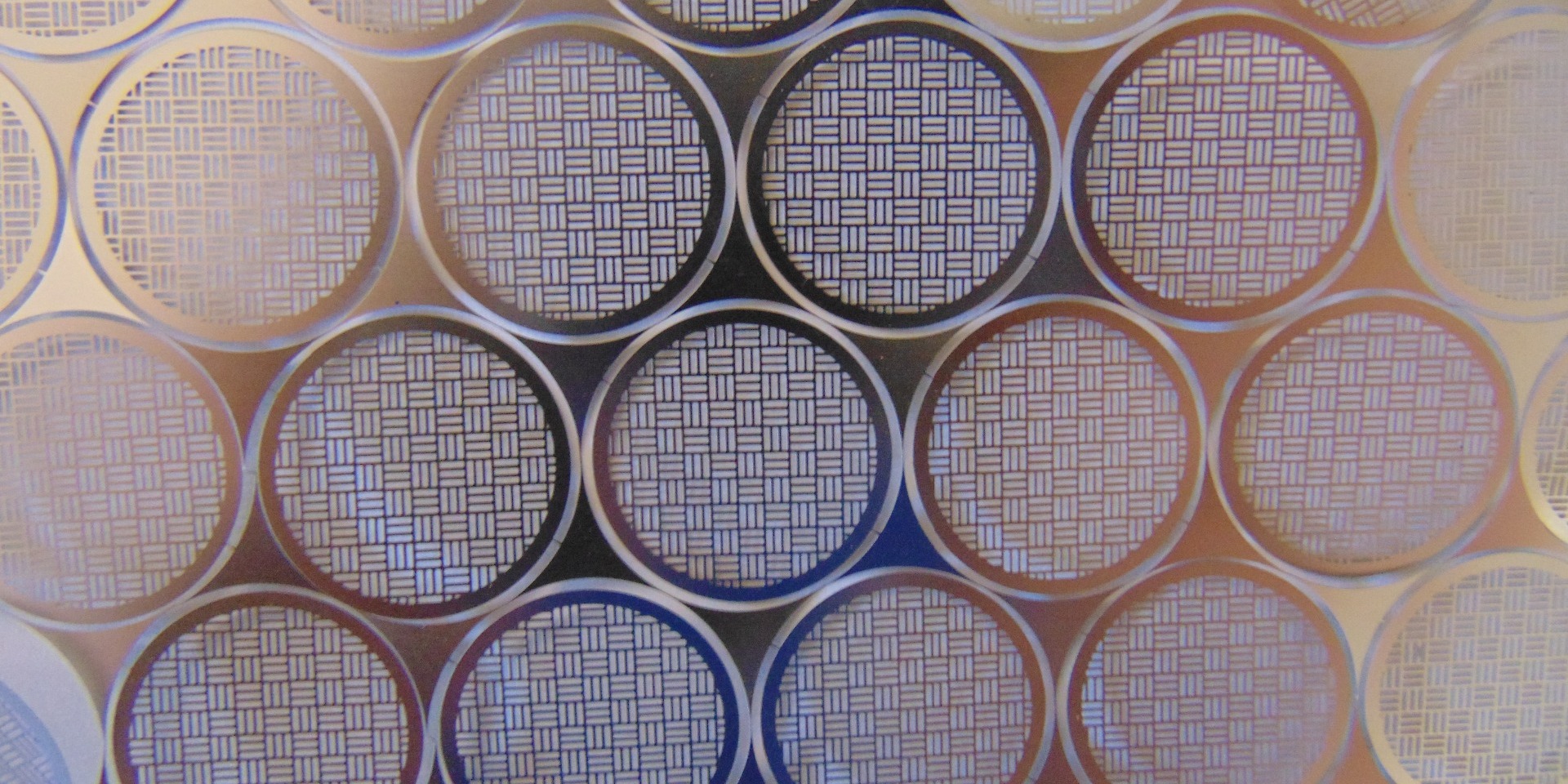

Etch Tech are able to manufacture meshes and filters from a wide range metals, including hardened nickel and stainless steels. Photo etching produces burr and stress free meshes. This results in greater efficiency and material integrity and wouldn't be possible with alternative methods such as punch perforation.

Metal meshes can be used to screen or prevent unwanted things such as pests; metal filters are used in filtration, for example scientific and laboratory air filtration systems. Metal grids, screens, meshes, filters and grilles to be used in industrial, decorative or architectural applications can all be manufactured by the chemical etching process

Photo Chemical Etching is the ideal process choice for the manufacture of any metal mesh . or metal filter components as the cost-driver is the size of the plate, or sheet, rather than the number of holes or apertures upon it. This means that the photo chemical etching process is consistently more cost effective for the production of metal mesh, a metal filter, and their components, than other processes, such as laser cutting. Furthermore, the finished mesh or filter can be produced at a tight tolerance, stress and burr-free.

Etch Tech supplies etched meshes and filters to a wide range of industries, including:

Architectural Installations

Decorative

Industrial

Interior Design

Luxury constructions, such as super-yachts

Etch Tech can supply Photo Chemically Etched metal Meshes and Filters in the following materials:

Aluminium

Beryllium Copper

Brass

Copper

Molybdenum

Nickel

Nitinol

Phosphor Bronze

Stainless Steel

Steel

Titanium

Thickness range 0.00508mm (0.0002") to 1.5mm (0.060")

Design tolerances

The Photo Etching process in place at Etch Tech Ltd is capable of etching extremely fine detail into metal. We have extensive experience working closely with customers to offer improved design tolerances on our meshes and filters. Please contact our design engineers so discuss your requirements.