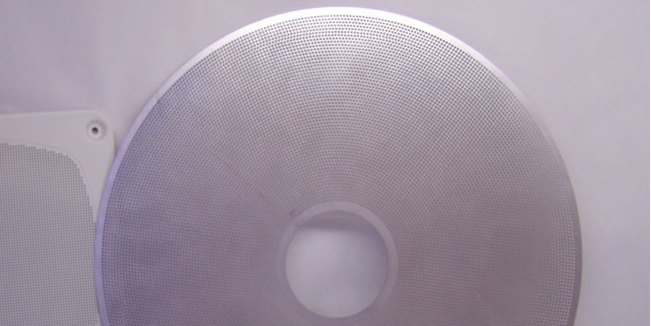

Benefits of the Photo Etching Process :

Apertures on both sides as the etchant works on both sides of the metal

Burr & Stress-free manufacturing method

Custom parts – you design it – we make it!

Cost-effective Prototyping

Etch Tech can call on more than 30 years experience in the photo chemical etching of metal components

High Accuracy

Low cost tooling

Industry leading lead times from inception to delivered components

Prototypes – fast turnaround to meet your needs

Scalable through Short Run to High Volume

To find out more about our Photo Etching Process please email, or contact us on 01480 435 548